For any Job Order Contracting (JOC) program to succeed, project owners and contractors must benefit mutually. The former benefits by controlling costs through transparent pricing and creating spaces that meet user needs, and the latter benefits by having the potential for a steady stream of work.

But for contractors who are new to Job Order Contracting solicitations, the bidding process may be confusing or overwhelming at first because they are required to apply a coefficient (also called an Adjustment Factor) to a set of construction tasks priced specifically for the local market. The process differs from bidding out projects using traditional construction procurement methods and it takes some getting used to.

Even contractors familiar with the JOC process may need a refresher on calculating and applying a competitive coefficient. So, we put together some best practices using our 30+ years of Job Order Contracting experience.

The Gist

- A competitive JOC coefficient ensures a contractor can make a profit from a JOC project.

- Contractors must consider many costs in their JOC coefficients.

- JOC coefficients are often the primary factor in determining the awarded contractor.

What is a JOC Coefficient?

In Job Order Contracting, a coefficient is a multiplier on the cost of construction tasks listed in a Unit Price Book. Here at Gordian, we call our Unit Price Book the Construction Task Catalog®, or CTC for short. Most coefficients fall between 0.80 and 1.20, meaning they may increase or decrease the costs listed in the CTC. In effect, by applying a coefficient, a contractor is saying, “This is how much I need to be paid for these tasks to turn a profit.”

What Costs Should Be Included in JOC Coefficient?

In order for the contractor to receive a fair price for their work, a JOC coefficient should include all direct and indirect costs not included in the preset prices, and the contractor’s overhead and profit. Subcontractor overhead and profit should be factored in as well.

Business costs to include in a coefficient:

- Insurance, bonds and indemnification

- Supervision

- Project management

- Site superintendence

- Office management and equipment

- Business risks such as a lower-than-expected volume of work, smaller-than-anticipated job orders and material cost fluctuations

- Regulatory compliance, including permitting and reporting

- Security requirements

- Vehicles and gas

- Chemical toilets

- Gang boxes

- Storage containers

This list is just a sample, and it does not include everything a contractor should include in a coefficient. It’s a lot to think about. That’s why Gordian trains JOC contractors how to correctly calculate a coefficient at pre-bid meetings around the country.

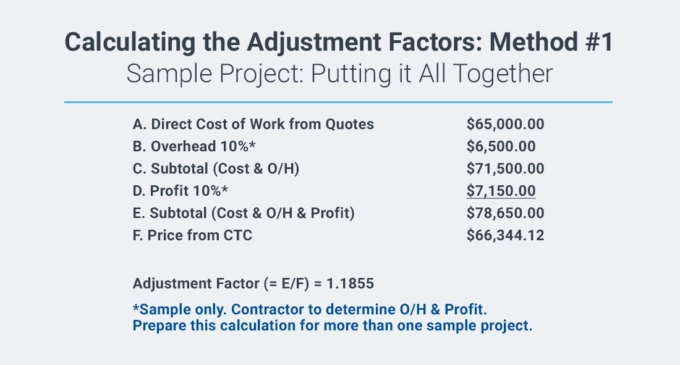

Calculating a JOC Coefficient Method One: Price Proposal Comparison

One effective way to calculate an accurate coefficient or Adjustment Factor is to use the owner’s Unit Price Book (published at the time of solicitation) to re-price successful proposals. After you’ve gathered all the unit line items necessary for the project, be sure to add your overhead, profit and other considerations such as general conditions. You’ll need them to calculate your coefficient.

Compare the total from your original Price Proposal with the mock proposal you built from the Unit Price Book. The new total might be more or less depending on construction material, labor and equipment costs in your local market and other circumstances. It is important to account for the overhead and profit of your original proposal, as that is priced into a JOC coefficient. To establish your coefficient, divide your subtotal by the price you built from the Unit Price Book.

We recommend repeating this exercise a handful of times to get acquainted with using a Unit Price Book and to determine a fair coefficient for your local market.

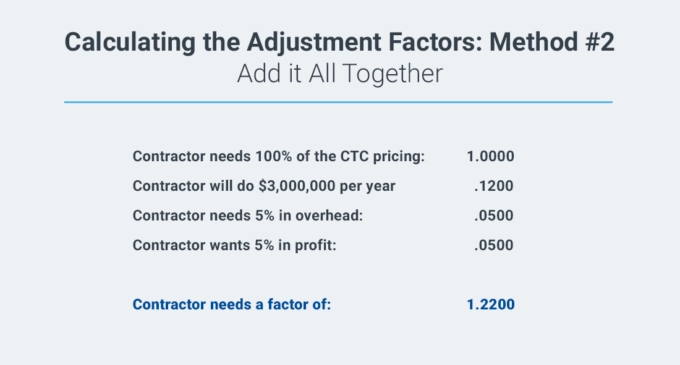

Calculating a JOC Coefficient Method Two: Use General Conditions

Another way to develop a coefficient or Adjustment Factor is to calculate your general expenses for the first year of a JOC contract. The owner will typically make public the value in their solicitation, giving you a solid idea of the volume of construction work they will order from contractors for each year of the contract. Add up your general conditions expenses for the year and divide that number by the amount of work you expect to do under the JOC contract for that year.

Once you’ve done that division, determine your overhead, then your profit margin. These numbers will vary based on your market.

Finally, add these numbers, beginning with a number relative to one to represent how much of the Unit Price Book you need. For example, if you need 95% of the value of the Unit Price Book, this number would be 0.95. Express your general conditions expenses, overhead and profit as decimals. To continue this example, if your expenses are 0.1, your overhead is .05 and your profit is .05, your total coefficient would be 1.1500.

Applying a JOC Coefficient

Here’s how to apply a coefficient for a JOC project. Let’s say the cost for a certain construction task is $20,000.

Contractor A: Applies a coefficient of 1.1215. That makes the total cost for the task $22,430.

Contractor B: Applies a coefficient of 1.1000. That makes the total cost for the task $22,000.

In this example, Contractor B is the lowest responsive, responsible bidder. In a typical contracting environment, Contractor B would be awarded the contract.

Now that you know what a JOC Coefficient is and how it’s applied, let’s dig into some best practices for calculating one for JOC project.

Read the Solicitation Carefully

In order to prepare to calculate a new coefficient, you must take into account bid considerations, including:

- Annual anticipated volume of work

- Type of work expected

- Construction site location

- Necessary staff

The JOC solicitation should, at minimum, provide an annual anticipated volume of work and the type of work that is typical or expected for the life of the contract. This information will inform whether a contractor has the capacity and/or the expertise to take on the type of construction work the owner demands.

Contractors should note and consider the location of the work when calculating a coefficient as well. A college campus may be an easier site to manage than a state prison system.

Finally, some JOC solicitations require a contractor to submit a staffing plan with the bid package and may even require minimum staffing levels for the duration of the contract.

Get detailed advice about running a successful Job Order Contracting program, from program setup to JOC project selection through measuring success, on our interactive Job Order Contracting Best Practices page.

Get Subcontractor Input on the Unit Price Book

Applying a coefficient to a Unit Price Book can be a foreign concept for many contractors, and one they may meet with hesitation. Good, successful contractors are used to bringing the costs of a construction project to the owner. Job Order Contracting flips that paradigm and the owners bring costs to the market via a coefficient applied to a Unit Price Book.

To help quell their apprehension, Gordian recommends contractors re-price an existing project – an exercise described earlier in this post. We also recommend asking subcontractors to review the CTC. These tradespeople are much more aware of cost variations and can review the details in their section of a price book quickly and efficiently and compare that to the prices they are accustomed to paying locally.

Keep in mind that the coefficient reflects the contractor’s understanding of the value of the unit pricing and is often the primary factor in determining which contractor wins the award. By the time of the solicitation, the owner has selected a source for pricing data to bid a coefficient against, so the only control that the contractor has with regards to price is the number that will be multiplied against the book.

Evaluate Risk of an Unrealistically Low JOC Coefficient

Business development teams must properly evaluate the risk of bidding a low coefficient. A low bid might win a contractor a job, but, ultimately, it will set up the team for failure and create a scenario wherein the contractor may feel forced to add unsupportable items or exaggerated quantities to a proposal, which in turn takes longer to review and leads to delays in Job Order development. Worse yet, once project owners or their Gordian representatives discover those unnecessary items or inflated quantities, trust between owner and contractor is broken, often irrevocably.

The consequences of turning an owner/partner into an adversary are dire for a JOC contractor. An owner may decide to reduce their volume of work. There’s also the “nuclear option,” where owners elect to let a contract expire without picking up its option.

So how does a contractor avoid this scenario? Start by asking subcontractors, project managers and estimators to weigh in on anticipated costs. The input from the end-users can help mitigate the risk of a bid coefficient that is unrealistically low.

A Fair JOC Coefficient Creates Shared Success

These tips and best practices will help a JOC contractor develop a fair and accurate coefficient that will help them win bids and continue to be successful after the contract is in place. While every single solicitation should be evaluated on its own terms, experienced JOC contractors are adept at following Gordian’s recommended process, creating a mutually beneficial relationship between them and their project owners.